Salce Volumetric Dispenser

The complete absence of pipes and valves reduces the maintenance times to the minimum, it avoids washings on transfer pipes and obstructions due to residual deposits and it remarkably speeds up the system.

- Designed on a modular basis, the machine can be supplied in different setups

- Upgradeable with the optional independent dyeing units

- Removable trolleys for 40 output beakers; trolleys can be customized to fit tubes of external dyeing machines

- Electronic accuracy: +/- 0.006 ml

- The machine allows the use of all dyestuffs and auxiliary products normally used in the dyeing laboratory

ACCURACY-SPEED-FLEXIBILITY

- MINIMUM SPACE

The complete absence of pipes and valves reduces the maintenance times to the minimum, it avoids washings on transfer pipes and obstructions due to residual deposits and it remarkably speeds up the system.

- Designed on a modular basis, the machine can be

supplied in different setups

Number of bottles on demand (in steps of 24)

Upgradeable with the optional independent dyeing units

- Removable trolleys for 40 output beakers; trolleys can be customized to fit tubes of external dyeing machines

The machine allows the use of all dyestuffs and auxiliary products normally used in the dyeing laboratory

- Average productivity of 50 recipes/hour (with 5

components each) - The use of a special, very high grade glass pipette

grants a high accuracy standard and repeatability in the measurement

- Real-time check of each dosing and mechanical error Controlled by dedicated PC and software

- Customized washing of the pipette for each product with the possibility to have a special rinsing with detergents

-Alternate stirring on all the bottles

Automatic water filling in order to preserve the programmed bath ratio

Electronic accuracy: +/- 0.006 ml

Saveco Heat Recovery System

Waste Heat Recovery System

With the aim of accelerating awareness about the importance of conserving energy, increasing productivity, optimizing the resources, and increasing sustainability, SaveEco Energy India is offering �Waste Heat Recovery System� and �Energy Conservations Solutions�.

- Exhaust Gases of Boilers and Fired Heaters

- Hot Air for process or as a combustion air

- Steam (if the gas temperature is sufficiently high)

- Resource Optimization- Recovery to the full extent possible

- Improves productivity and sustainability

Solutions can also be availed where Waste Heat exists but the consumer is not available-

� Hot water to be used for running a Vapor Absorption Chiller. Even low grades of heat (hot water temperature 70�C) can be used

� Generate power by using the Organic Rankine Cycle (ORC) Turbine

SaveEco has expertise in building and facilitating clients with Energy Conservation services like-

� Waste Heat Recovery from Compressors (in the form of hot water)

� Waste Heat Recovery from other processes

� Converting Gas/Oil Fired Boilers and Heaters to Biomass Briquettes Fired system. These are identified as Green Fuels by CPCB and create low pollution and offer very attractive payback

� Smart Kitchen solutions for Industrial Kitchens substantially reduce fuel consumption in kitchens by using Solar Powered Hot Oil or Steam-based systems, coupled with particularly designed cooking vessels.

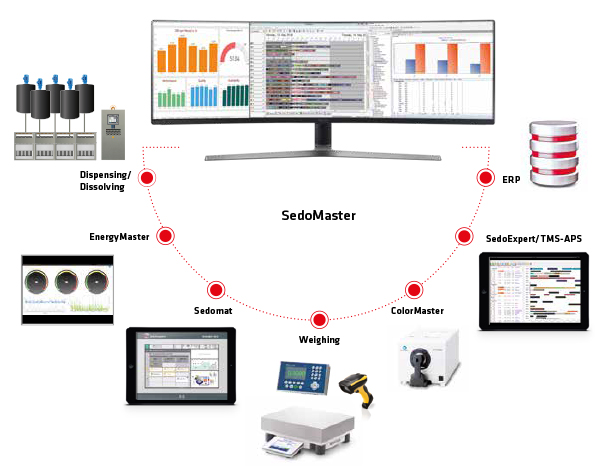

Sedo-Treepoint SedoMaster

SedoMaster connects all systems of the dyehouse or textile finishing plant in one system. For production planning from batch start to batch end and all related processes.

- Supports new Sedomat 6000/8000 Series as well as other Sedomat controllers

- Provides IIoT-enabled production for the Smart Factory

- Production control leads to increased productivity and quality improvement

- Real time interactive planboard, powerful reporting and dashboard

- Single, integrated view of production data for improved decision-making

All the advanced functionalities and capabilities to create a connected production environment in a dyehouse or textile finishing plant are provided. SedoMaster is a central tool for the entire workshop to get real-time insights for better production and business performance. It helps to better understand operations and to get more out of workforce, equipment and materials.

POONGKWANG MACHINE Compressive Shrinking Range

Dyeing processing machine manufacturer, PTFE facility, Gas singeing machine, Compactor, Textile machine and more

- Supplying evenly sufficient amount of moisture and steam on the surface of the fabric.

- High compressive shrinking effect of rubber belt.

- Good effectiveness with the felt dryer

- Automatic control of shrinking ratio.

- Different Model Available

..

kiraymakina

K?ray Makina produces high efficient, durable and high quality machines for the textile industry. Products Range:

- Tubular Slitting Machine

- Tubular Squeezing Machine

- high quality machines

- Pre-Stenter Washing Machine ROY-1991�

- Tubular Squeezing Machine

..

WESTENTER Model Stenter Machine

WESTENTER is designed for the heat setting, drying and finishing processes of open width knitted and woven fabrics. It offers the best results with its state-of-the-art equipment and low energy consumption. It has a wide variety of versions according to needs.

- High Level Repeatability

- High Quality and Wide Variety of Production

- Lower Energy and Water Consumptions

- Minimized Environmental Impact

- Easy to Operate

..